Quality control

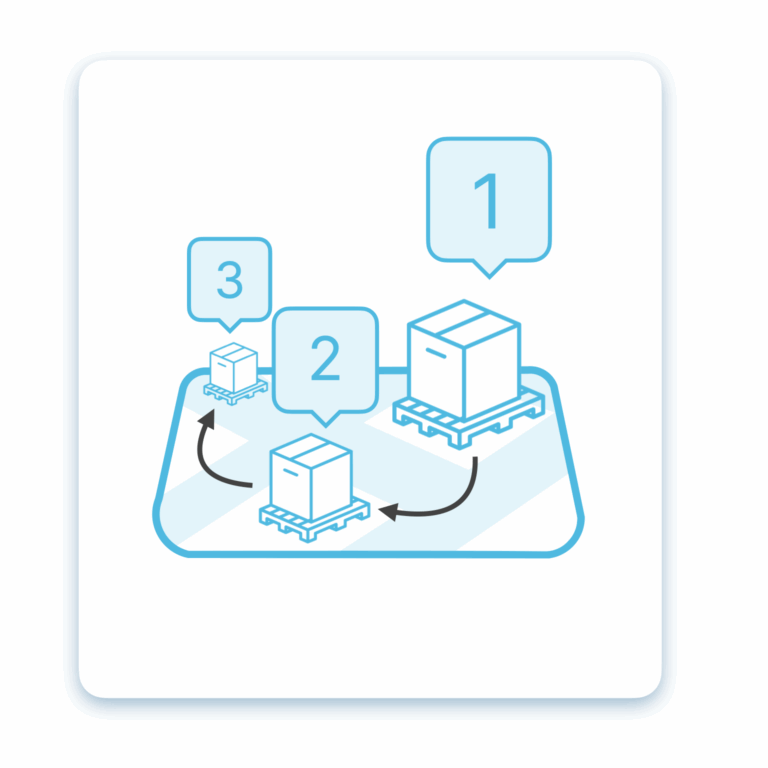

Process Step Verification

Each time a product reaches a key station, the system confirms and logs the event. If a step is missed or repeated incorrectly, it’s flagged in real time, ensuring process integrity and traceability

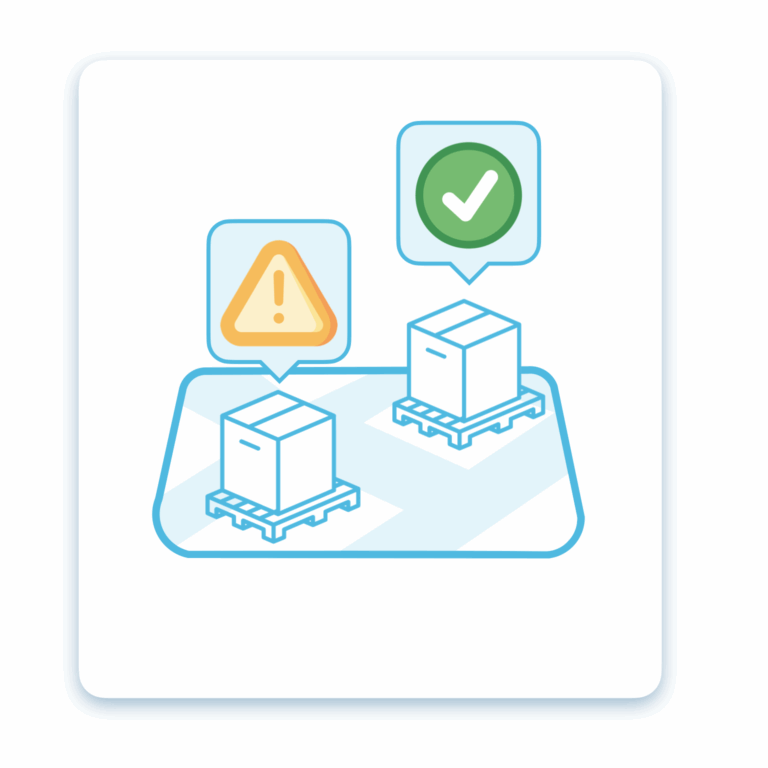

Exception reporting

Automatically identifies deviations such as skipped stations, delays, or misrouted items. These alerts help quality control teams take quick corrective actions, improving accountability across shifts

Waste Reduction

Catching process errors early prevents flawed products from reaching later stages or customers. This reduces scrap, rework, and returns—saving material, time, and reputation while improving your Carbon Disclosure Project (CDP)

Root Cause Traceability

When a defect is found, you can trace it back to the exact step, location, and time it occurred. This speeds up troubleshooting, protects batch integrity, and avoids repeated mistakes