Asset Tracking

Location history

Every tracked asset has a digital breadcrumb trail, showing exactly where it’s been over time. This data is crucial for audits, process analysis, and uncovering inefficiencies related to asset flow across the facility

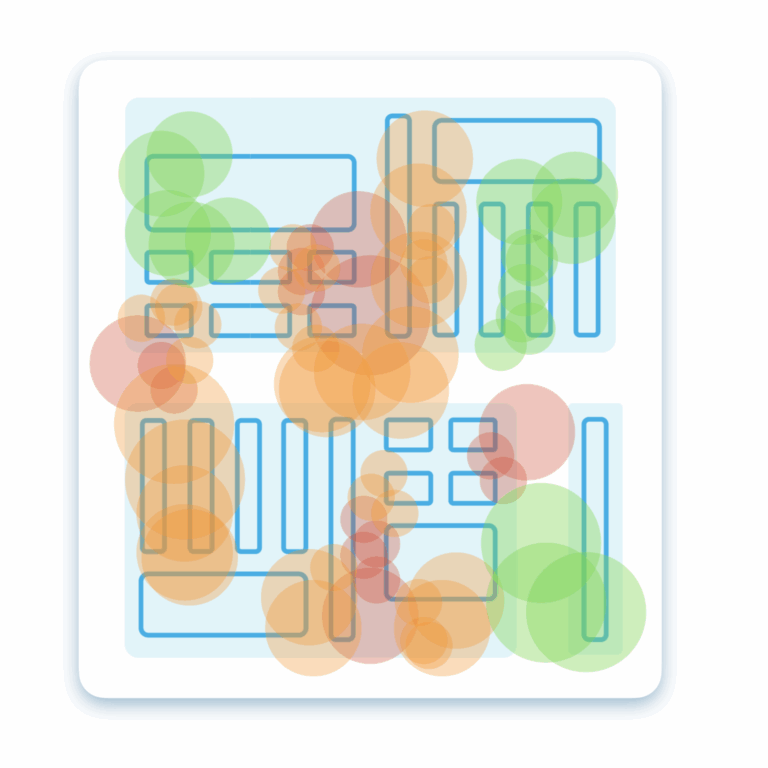

Real-time heatmaps

Visualize where tools and assets are most often located or left idle. These heat maps help identify underused zones or high-traffic areas, which can inform layout changes or asset redistribution to improve access and reduce downtime

Fewer lost tools

With live tracking and historical movement logs, misplacement of tools becomes rare. Maintenance and production teams waste less time searching for items, and replacements due to loss are significantly reduced.

Faster Retrieval Times

By knowing where each asset is at all times, employees can go straight to what they need. This speeds up task execution, minimizes idle time, and improves overall job efficiency, especially in large facilities.